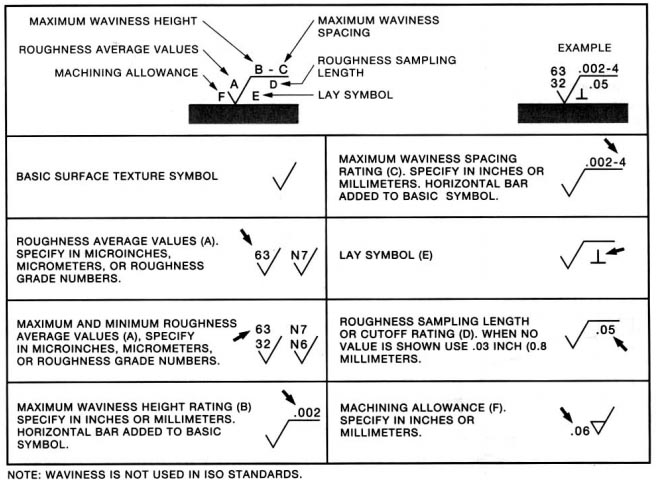

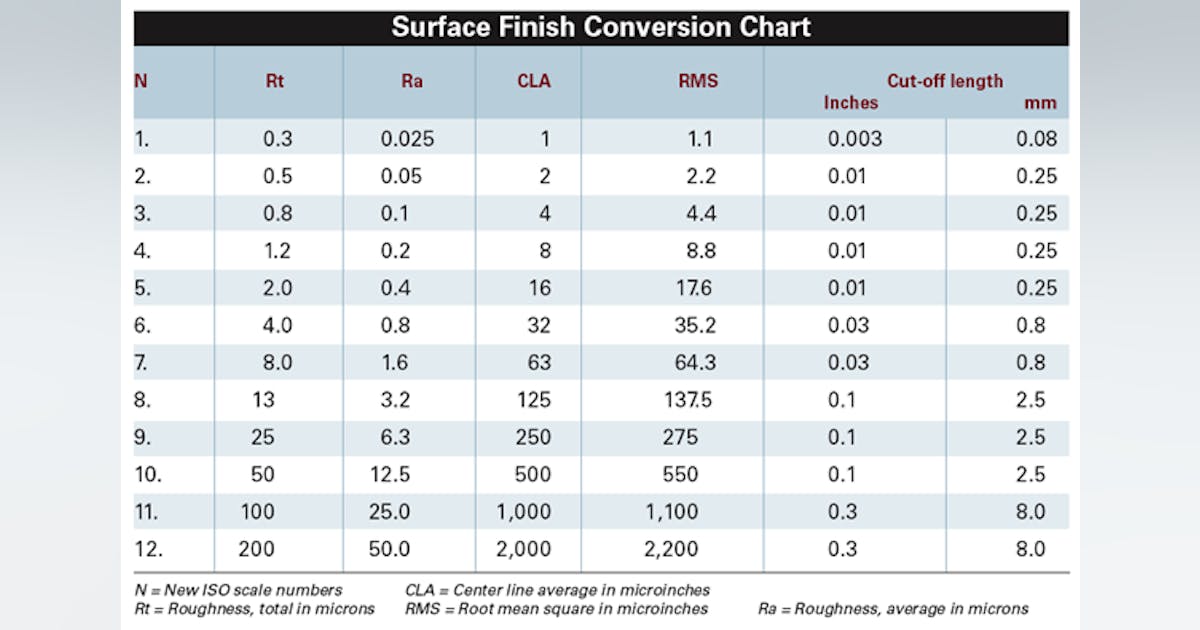

How to deal with the surface finish for your precision CNC machine parts. | CNC Precision Machining Service

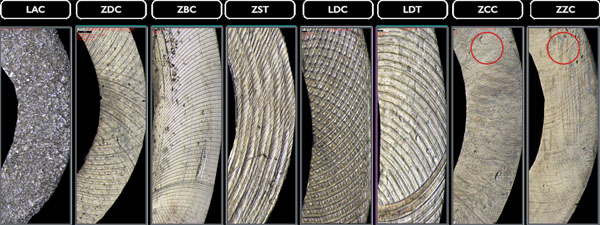

Surface Roughness and Necessity of Manual Refinishing Requirements of CAD/CAM-Manufactured Titanium and Cobalt-Chrome Bars – A Pilot Study

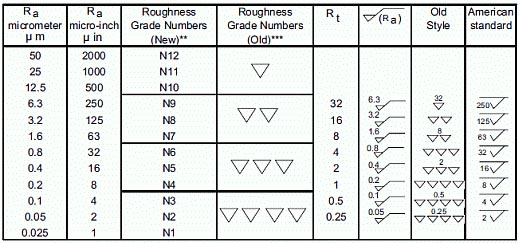

Xometry Europe - 💢 Selecting the right surface roughness for #cncmachined parts can be confusing. That is why we have made a guide for you to be able to select the best

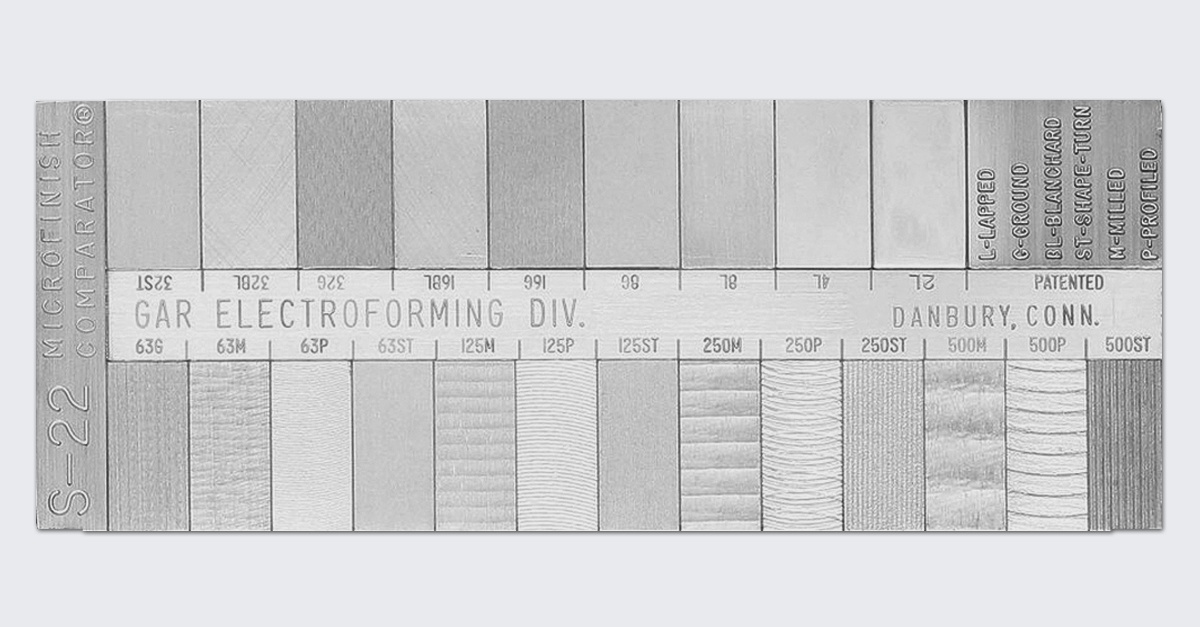

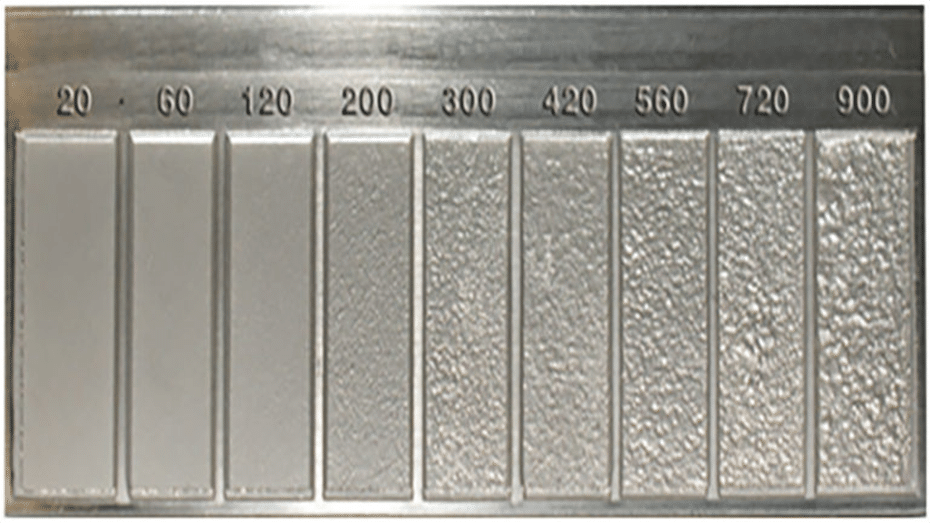

SPI - 0.1 to 3.2 RA micro m Surface Finish, Nickel, Surface Finish Comparator - 06558266 - MSC Industrial Supply

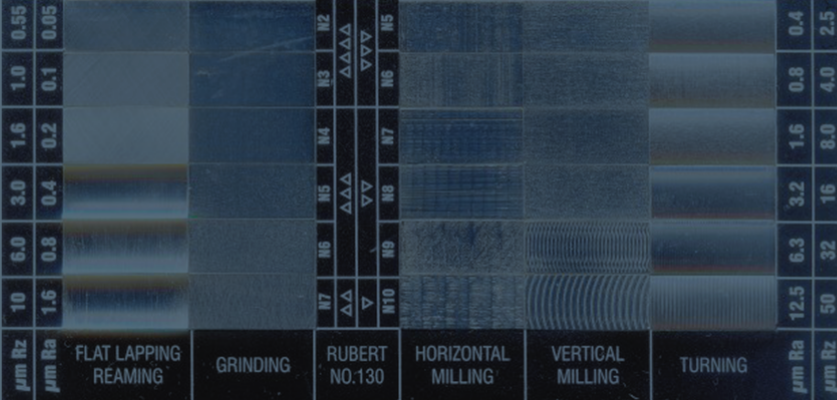

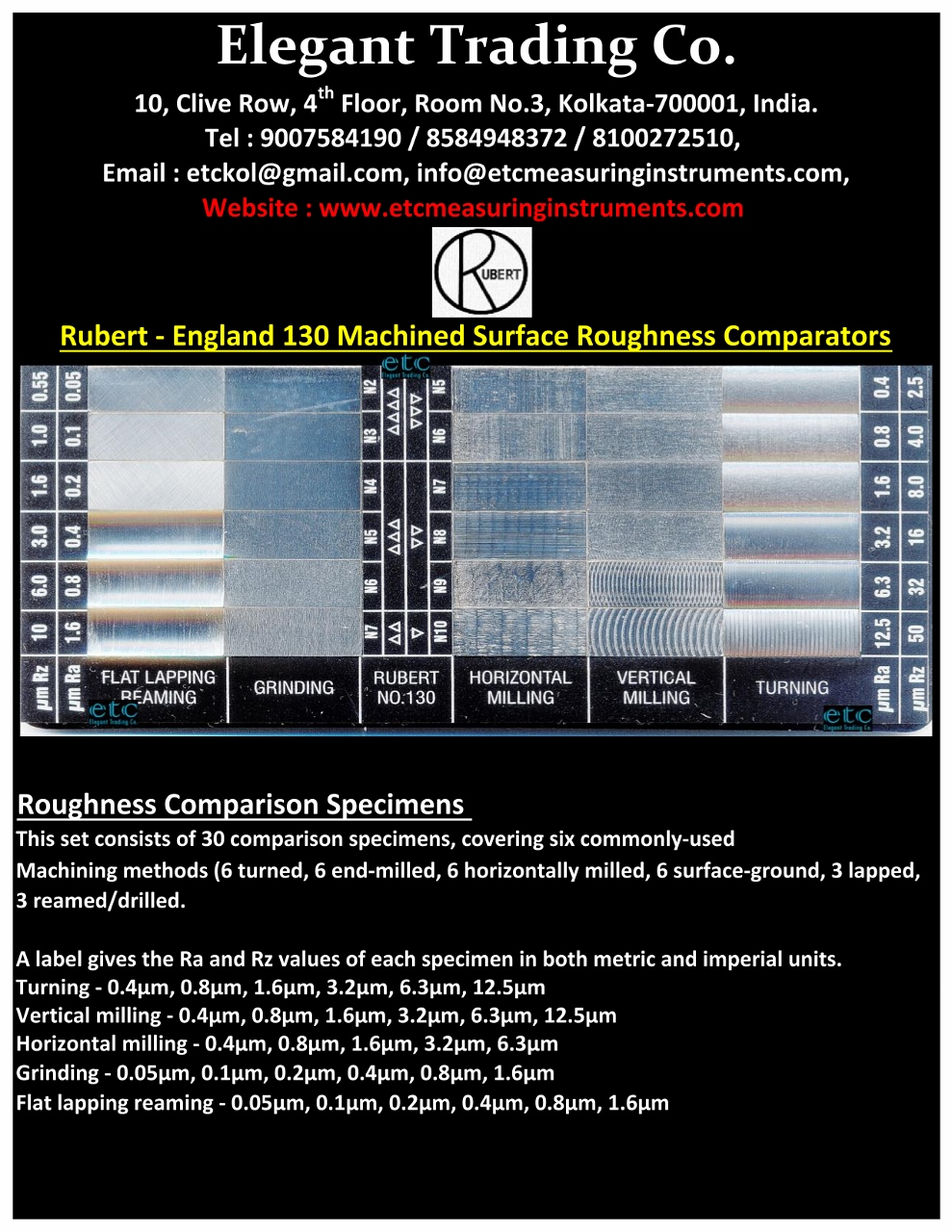

Rubert 130 Machined Surface Roughness Comparator, Flat Lapping, Reaming, Grinding N2, N3, N4, N5, N6, N7 Parameters, Horzontal Milling, Vertical Milling, Turning Roughness Specimens. – Testing, Inspection & Measuring Instruments Dealers in

Alternative Surface Roughness Measurement Technique for Inaccessible Surfaces of Jet Engine Parts Using the Rubber Silicon Replica Method | SpringerLink